- CURRENT TRANSDUCER 4 TO 20MA OUTPUT FACTORY FULL

- CURRENT TRANSDUCER 4 TO 20MA OUTPUT FACTORY SOFTWARE

For easy understanding only, both 20mA & 4 mA signals are shown in the animation. Note: The loop current will be same either at starting or end or any point in the loop. The Analog to Digital converter will be used to convert the voltage into digital signal which is used to indicate the Process Variable value in the DCS / PLC HMI.

The 4-20mA current will be converted into standard 1 – 5 V DC using a precision 250 ohms resistor. The Transmitter will be configured with LRV, URV and other details of Process variable. The loop current will be varied / changed by the transmitter as per the measured Process variable. Transmitter have an inbuilt voltage regulator function which is used to regulate the loop current. In Practical there will be a voltage drop in the loop. A minimum +5V DC, 20mA signal is required to proper functioning of transmitter. Transmitter receives +24V DC, more than 20mA signal in the loop. Case 1 : Process Variable PLC / DCS Analog Input card transmits a standard +24 V DC, 20 mA signal to Power the Transmitter.Ī one pair cable is used to power the transmitter and the same cable is used to receive the data in the 4-20mA current range. In General PLC / DCS Analog Input card channel supplies more than 20mA current to power the loop. When considering a flow transmitter, for example, the range of the measurand or Process Variable is 0.0 to 100.0 m3/hr, corresponding to a 4- to 20-mA loop current (output span is then 16 mA) the output scaling factor is 0.16 mA/(m3/hr) (which is 100 m3/hr 16 mA). Thus, the span corresponds to the indicated range of the measurand or Process Variable.

CURRENT TRANSDUCER 4 TO 20MA OUTPUT FACTORY FULL

The difference between Zero and full scale, 16 mA, is called the span. With the 4- to 20mA range, the loop current is normally 4 mA when the measurand or Process Variable is at zero, and 20 mA when the measurand or Process Variable is at full scale. Important calibration parameters with a current loop are Zero, full scale, and span. The standard loop current is usually 4 to 20 mA.

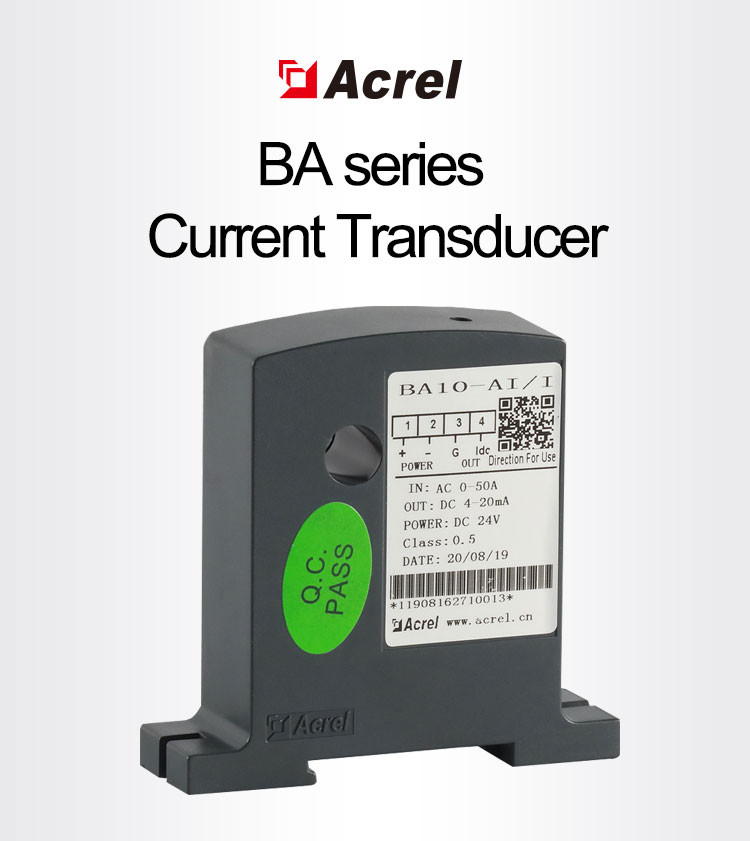

Some popular names for the sensing devices that provide the information are sensors, transducers, and/or transmitters. To facilitate a closed-loop control system, information from the process must be obtained before a controller can determine what action may be required by a control element.

This is generally the basic configuration for industrial process control systems when digital communication is not required.Īs shown in Below Figure, only two wires are used to accommodate both power to the transmitter and output signal from the transmitter. The most common and easiest to use is the two-wire, loop-powered configuration. Transmitters can have any of several electrical connection schemes. The term “transmitter,” as commonly used with industrial process control instrumentation, has a more narrow definition than those of a sensor or transducer: 4-20 mA TransmitterĪ transmitter is a transducer that responds to a measured variable by means of a sensing element and converts it to a standardized transmission signal (like 4-20mA) that is a function only of the measured variable. The receiving electronics can be an indicator, controller, computer, PLC, DCS etc. Its output is conditioned and ready for use by the receiving electronics like PLC or DCS. The measurand is the physical parameter to be measured.Īn input transducer produces an electrical output that is representative of the input measurand. A sensor is also commonly called a sensing element, primary sensor, or primary detector. Other applications include security and condition monitoring, load monitoring, in protection systems, and for predictive maintenance of conveyors, pumps or HVAC motors.A sensor is an input device that provides a usable output in response to the input measurand.

CURRENT TRANSDUCER 4 TO 20MA OUTPUT FACTORY SOFTWARE

It may also be applied for current measurement in a system of distributed power line carriers (PLCs) or remote controls such as SCADA software for automation and supervision. The Current Transducer 4-20mA DC, JC16F-RMS Series, is designed for energy management, with a convenient connection type to electronic sub-meters.

0 kommentar(er)

0 kommentar(er)